Robot safety

The BBH Products Safety controls are excellent safety related tools for robot cells and robot system technology.

- The requirements for robot safety are continuously growing

- Not only 6 axis robots has high demand for robot safety for instance in automotive or packaging industries

- Smaller robots has a strong demand for men-to-machine collaboration

- Applications with delta robots, SCARA Robots and linear robots especially in Pick-and-Place needs safety related shut down and reduced motion functions

- Up-to-date standards demand safe motion for robots

- Work cells can not any more closed and separated, there is always a requirement for motion within a open cell

Normative approach

The following international standards are demanding safety of robot motion

- ANSI B11.0-2010 –Safety of Machinery –General Requirements and Risk Assessment

- ANSI B11.TR3-2000–Risk Assessment and Risk Reduction –A Guide to Estimate, Evaluate and Reduce Risks Associated with Machine Tools

- SEMI S10-0307–Safety Guideline for Risk Assessment and Risk Evaluation Process

- MIL-STD-882D-2000–Standard Practice for System Safety

- CSA Z432-04–Safeguarding of Machinery –Occupational Health and Safety

- CSA Z434-03–Industrial Robots and Robot Systems –General Safety Requirements

- CSA Z460-05–Control of Hazardous Energy –Lockout and Other Methods

- NOM-004-STPS-1999–Protection Systems and Safety Devices for Machinery and Equipment used in the Workplace

- UNE-EN ISO 10218-1 Robots and robotic devices -Safety requirements for industrial robots –

Part 1: Robots and robotic devices -Safety requirements for industrial robots -Part 1: Robots - UNE-EN ISO 10218-2 Robots and robotic devices -Safety requirements for industrial robots –

Part 2: Robot systems and integration Robots and robotic devices -Safety requirements for industrial robots -Part 2: Robot systems and integration - ISO 14120 Safety of machinery –Guards –General requirements for the design and construction of fixed and movable guards

- ISO 14118:2000 Safety of machinery –Prevention of unexpected start-up

- ISO 12417+A2 Machine tools -Safety -Machining centers -Machine tools -Safety -Machining centers

- ISO 14159 Safety of machinery –Hygiene requirements for the design of machinery

- ISO 21469 Safety of machinery –Lubricants with incidental product contact –Hygiene requirements

- ANSI/RIA R15.06-1999 (R2009)–For Industrial Robots and Robot Systems –Safety RequirementsNFPA 79-2012 –Electrical Standard for Industrial Machinery

- ANSI/ASSE Z244.1-2003 (R2008) –Control of Hazardous Energy –Lockout/Tagout and Alternative Methods

- ANSI/PMMI B155.1-2011–Standard for Packaging Machinery and Packaging-Related Converting Machinery –Safety Requirements for Construction, Care, and Use

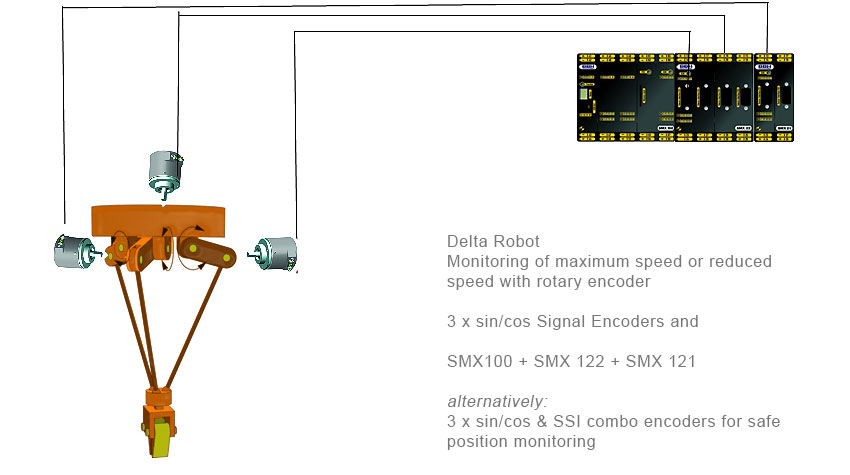

Pick and Place Robots

Pick and Place tasks are achieved by various robot designs.

The SMX Product range delivers the right solution to various models

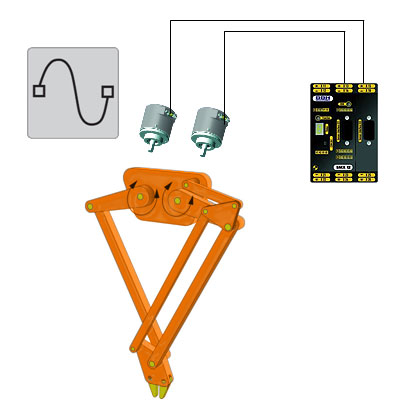

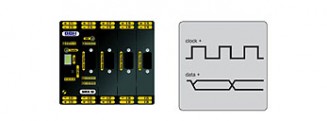

2 D parallel kinematics

Monitoring of maximum speed or reduced

speed with rotary encoder

2 x sin/cos Signal Encoders and SMX12

alternatively:

2 x sin/cos & SSI combo encoders for safe

position monitoring with a SMX 12-2

Pick and Place Robots

Pick and Place tasks are achieved by various robot designs.

The SMX Product range delivers the right solution to various models

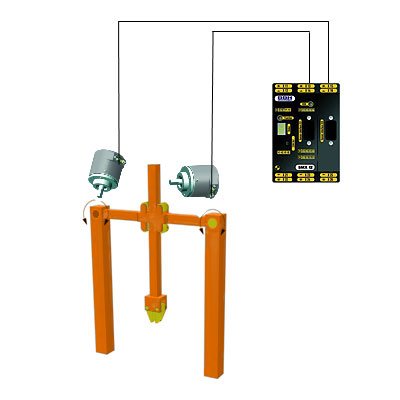

Roller kinematics

Monitoring of maximum speed or reduced speed with rotary encoder

2 x sin/cos Signal Encoders and SMX12

alternatively:

2 x sin/cos & SSI combo encoders for safe position monitoring with SMX 12-2

Pick and Place Robots

Pick and Place tasks are achieved by various robot designs.

The SMX Product range delivers the right solution to various models

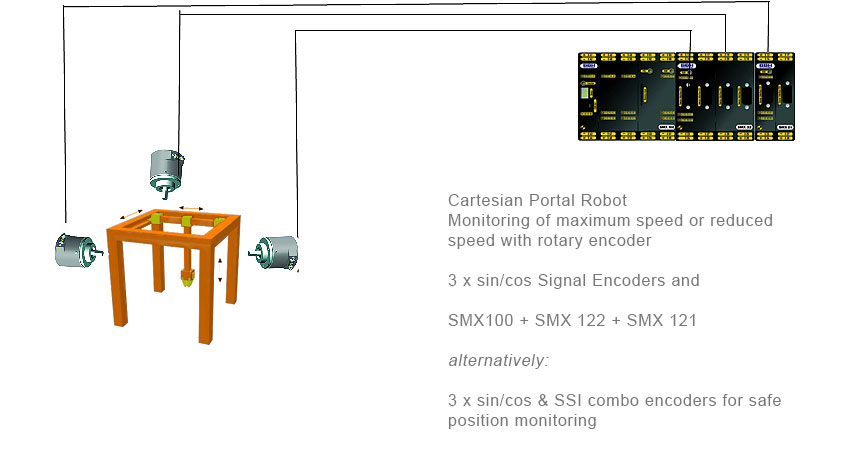

Pick and Place Robots

Pick and Place tasks are achieved by various robot designs.

The SMX Product range delivers the right solution to various models

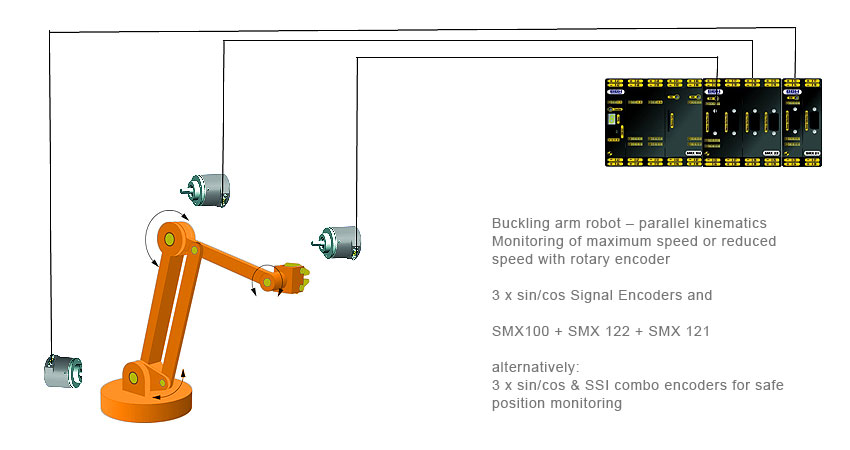

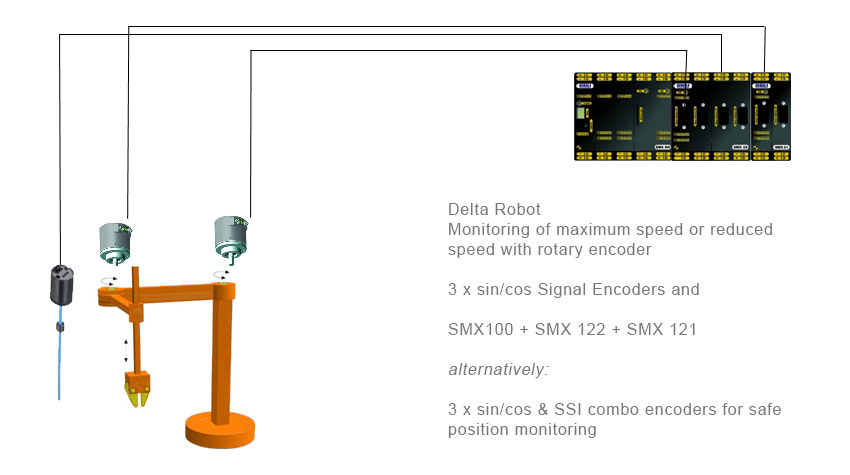

Pick and Place Robots

Pick and Place tasks are achieved by various robot designs.

The SMX Product range delivers the right solution to various models

Pick and Place Robots

Pick and Place tasks are achieved by various robot designs.

The SMX Product range delivers the right solution to various models

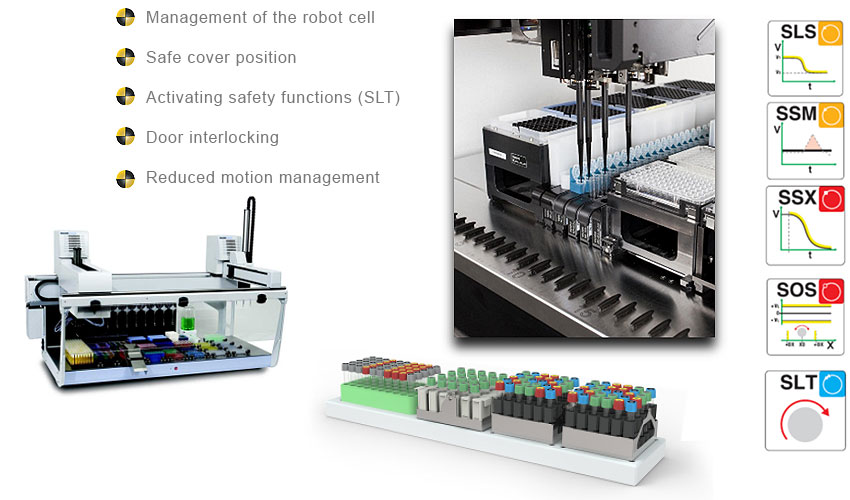

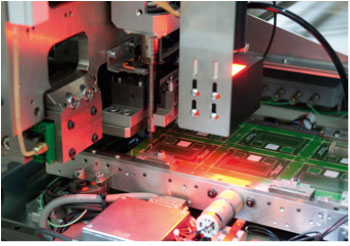

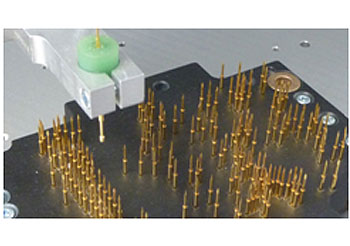

In the field…..

Producer of PCB production lines. All kind of Pick & Place scenarios.

Reduced speed, when cover is opened.

In the field…..

Liquid transporter for in vitro diagnostics according to IVD directive